DCRPROGETTI

DCRPROGETTI Progettazione e consulenza Design&Consultants

Papers

Industrial plants for bulk materials handling

DCRPROGETTI presentation at the XXVIII Congress on metal structures organized by C.T.A. held in Francavilla al Mare (Pescara) in 2022.

The aim of this document is to illustrate the peculiarities that characterize a particular sector within industrial plants, that is the one that deals with the handling of bulk materials. A first part will be used to describe the various equipment that make up the plant, such as the different types of conveyors, belts, driving and tail heads, counterweights, hoppers and all the other fundamental elements for the loading, handling, unloading and storage of materials. It then continues with the identification of typical loads, "special" loads and the various stresses induced by handling. Finally, structural elements and types that are best suited to the service of the aforementioned equipment are identified, such as bridge beams, galleries, bents, loading towers, unloading towers or distribution towers with a focus on the main structural problems to be taken into account in the design.

Modular solutions in petrochemical facilities structural design

DCRPROGETTI presentation at the XXVI Congress on metal structures organized by C.T.A. held in Venice in 2017.

The structural modularization is often necessary for the construction of industrial plants. This technique allows to build in difficult sites with sustainable cost. A untraditional design approach is applied to this structures to ensure the best performance in all the construction phases and in operating conditions The need to guarantee the integrity of the equipment during the modules movements makes the transportation the most critical design condition. In this article some design experience are described focalizing the attention on the following phases: load-out, sea-transportation and load-in. The analysis techniques and the structural solution are here explained in order to give a description of the used design approaches.

Design of a industrial steel structure in the vibration limit state.

DCRPROGETTI presentation at the XXV Congress on metal structures organized by C.T.A. held in Salerno in 2015.

The steel structures in the industrial field often support rotary or reciprocal vibrating machines. These machines produce vibrations that spread throughout the structure up to the foundation. National and international codes impose limitations on vibrations, both for the proper functioning of the machines and for the protection of the health of the operators. In the case under examination, the industrial structure, partly in reinforced concrete and partly in steel, supports many vibrating machines at various elevations (fans, pumps, vibrating beds, mills) with very different vibration frequencies. Only with the use of a three-dimensional finite elements model and applying load time histories was it possible to grasp the structural behavior with respect to vibrations and therefore to proceed to an accurate design at the serviceability limit state.

Problems in industrial buildings in high-seismic zones – The power plants

DCRPROGETTI presentation at the XXIII Congress on metal structures organized by C.T.A. held in Ischia (Naples) in 2011.

The construction of buildings in power plant in highly seismic zone involves the resolution of important engineering problems. This paper illustrates a building for the desulphurization and the turbine hall analyzed by spectral analysis in accordance with Chilean code and its peculiarities. The most important details for each building are presented.

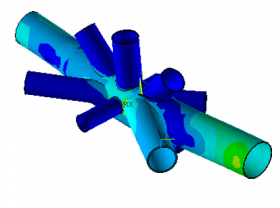

Evaluation of the SCF for Tubular Connection with Finite Element method

DCRPROGETTI presentation at the XXII Congress on metal structures organized by C.T.A. held in Padua in 2009.

An actual application using finite elements for Stress Concentration Factor (SCF) assessment in connections with fatigue problems of an oil drilling platform off Libya is illustrated. The procedure follows what is suggested by the fatigue international standards code.